Copyright © Dongguan Rongguang Automation Equipment Co., Ltd. All Rights Reserved. Site Map

- +86-13694981018

- rd@gd-rg.com

- Room 102, Building 1, No. 10 Yanhexi 1st Road, Dongkeng Town, Dongguan City, Guangdong Province

Project | Parameter |

Power supply | Three phase 380 |

Total power | 25KW |

Gas source | 0.3-0.5Mpa |

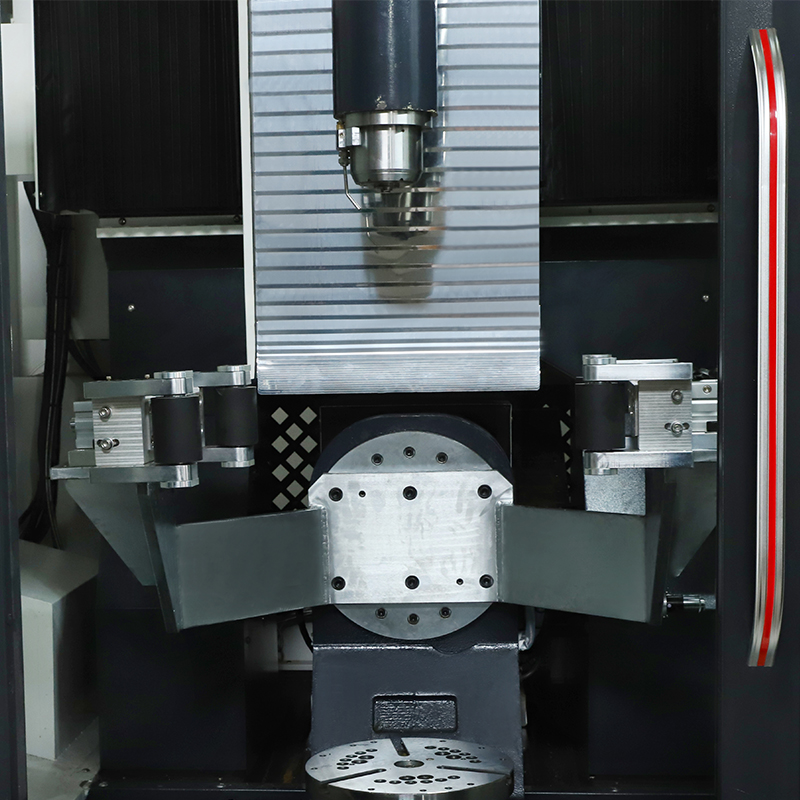

Workbench area | Φ350mm |

Accuracy | 0.01mm |

X, Y, Z positioning accuracy | 0.005mm |

X, Y, Z repeat positioning accuracy | 0.005mm |

Drilling spindle maximum speed | 30000rpm |

BC axis accuracy | 0.0008° |

B-axis rated torque | 4410N.m |

C-axis rated torque | 3136N.m |

Maximum torque of drilling spindle | 9.7N.m |

Maximum strokeX*Y*Z*B*C | 700mm*300mm*1200mm**±90°*360° |

Number of tool magazines | BT30-24T |

Tool changing method | Mechanical tool arm tool change |

Side milling head can automatically set the tool | Automatic tool setting |

Feed | 10m/min |

X, Y, Z axis rapid movement | 0-24000mm/min |

Cutting feed rate (X, Y, Z) | 0-10000mm/min |

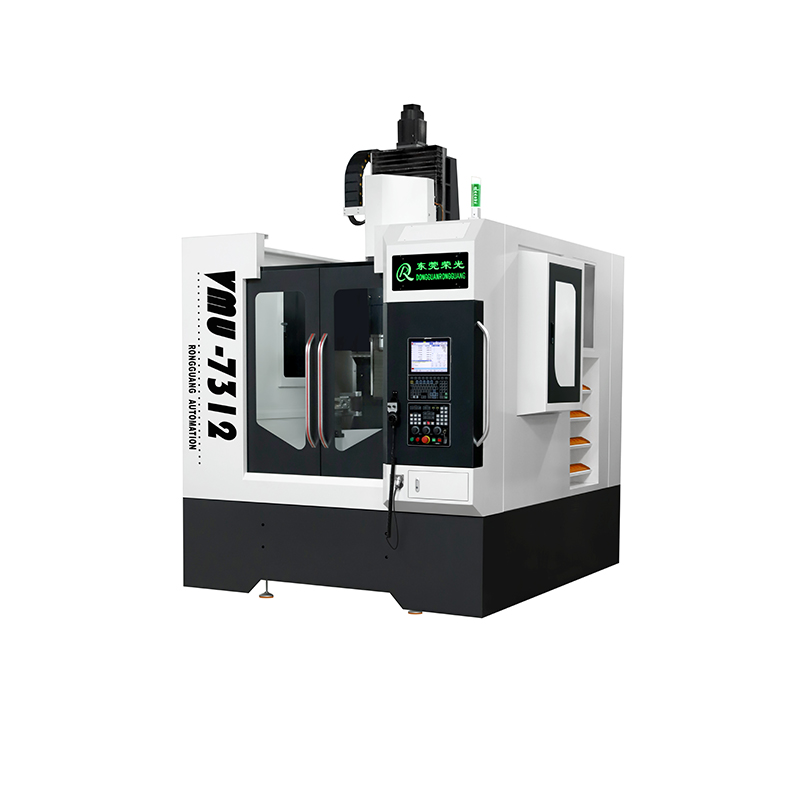

Overall dimensions (L*W*H) | L3300*W3200*H4000 |

Weight | About 8000KG |