Copyright © Dongguan Rongguang Automation Equipment Co., Ltd. All Rights Reserved. Site Map

- +86-13694981018

- rd@gd-rg.com

- Room 102, Building 1, No. 10 Yanhexi 1st Road, Dongkeng Town, Dongguan City, Guangdong Province

Model | LQ901 | LQ1001 |

Power supply | 220 V | 220V |

Power | 2.5 KW | 3KW |

Gas source | 0.3-0.5 M Pa | 0.3-0.5 M Pa |

Spindle | 0.8KW and 2.2KW | 1.5KW and 2.2KW |

Drill speed | 0-24000 r/min | 0-24000 r/min |

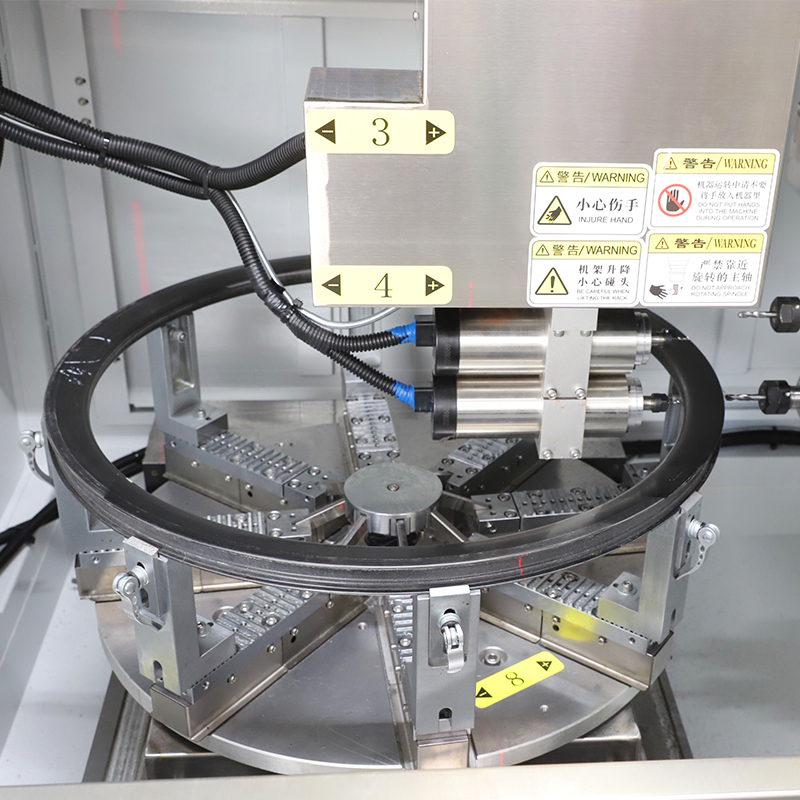

Types of holes processed at the same time | 4 types | 4 types |

Repeatability | 0.05-0.15 mm | 0.05-0.15mm |

Moving speed | 0-150 mm/s | 0-150 mm/s |

Rim range | Φ420-Φ700 mm | Φ420-Φ700 mm |

Inner hole AB/CD angle | ±12°/ ±10° | ±12°/ ±10° |

AB/CD angle of outer hole | 0° | ±12°/ ±10° |

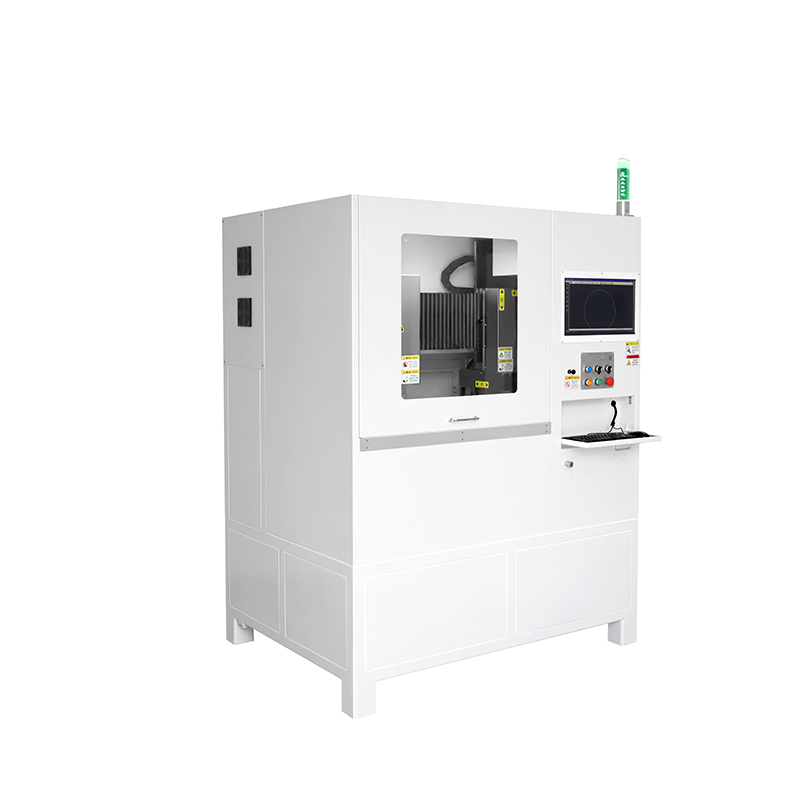

Dimensions | 1500mm*1200mm*1920mm | 2000mm*1650mm*2000mm |

Function Description | The valve hole and spoke hole can be drilled in one clamping operation, and the inner hole has A, B/C, and D angle deflections. | Based on LQ901, the outer hole can also be deflected at A, B/C, and D angles, and the inner hole wall can be chamfered to increase the contact area with the spoke cap, which is conducive to a more favorable release of spoke tension. |