Copyright © Dongguan Rongguang Automation Equipment Co., Ltd. All Rights Reserved. Site Map

- +86-13694981018

- rd@gd-rg.com

- Room 102, Building 1, No. 10 Yanhexi 1st Road, Dongkeng Town, Dongguan City, Guangdong Province

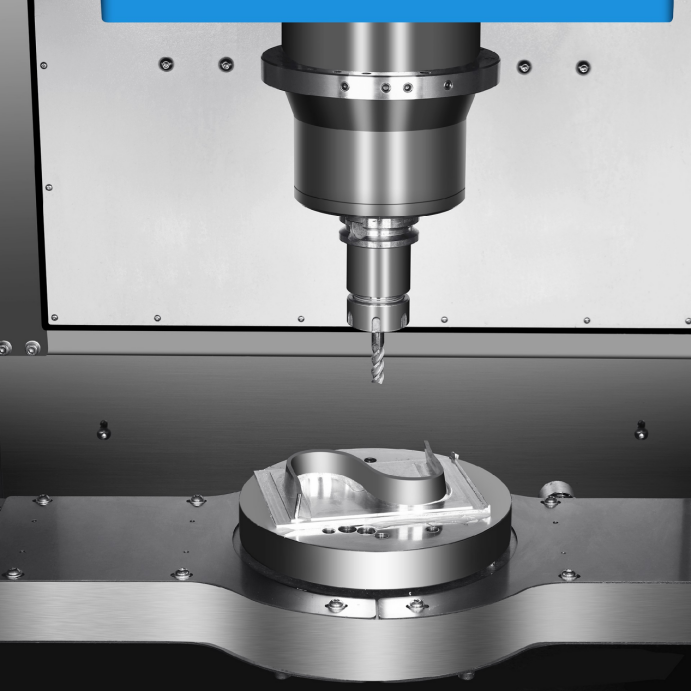

The five-axis linkage machining center has the characteristics of high efficiency and high precision, and can process very complex hardware parts. It is suitable for workpieces that require five-axis linkage to complete processing, and can be drilled and milled. The processed workpieces have high precision and good finish. There is a big difference between a five-axis machining center and a pentahedral machining center. Many people do not know this and mistakenly regard the pentahedral machining center as a five-axis machining center. The five-axis machining center has five axes: The "pentahedral machining center" is similar to the three-axis machining center, except that it can process five faces at the same time, but it cannot do special-shaped processing, punching oblique holes, cutting bevels, etc.

1. Suitable for processing complex special-shaped parts. Five-axis machining centers can process complex parts that are difficult or basically impossible to process with general machining centers. Therefore, they are widely used in aerospace, shipbuilding, mold and other processing industries.

2. High-precision processing. The five-axis machining center performs dimensional analysis on the material through five-axis positioning to complete the inspection, so the accuracy of the five-axis vertical machining center is higher than that of the ordinary machining center.

3. The processing is firm and firm. Computer control eliminates human errors, and parts processing has good consistency and stable quality.

4. High flexibility. When dealing with object conversion, generally only the CNC sequence needs to be changed, which shows good adaptability and can save a lot of time in production. Based on the five-axis machining center, an automated production system with high flexibility can be formed.

5. Efficient. The five-axis machining center has high machining accuracy. The bed has high rigidity and can automatically select the processing volume. The five-axis machining center has high productivity, which is generally 3 to 5 times that of ordinary machining centers. It can handle the processing of some complex parts and can increase the productivity by more than ten times. times or even dozens of times.

6. Good production conditions. The machine has a high degree of automation, the operator's work intensity is greatly reduced, and the working environment is better.

7. Conducive to management. The use of five-axis machining centers is conducive to the control and management of production and creates conditions for the automation of the production process.